Our Products

What we're good at

NTI designs and manufactures BOP lifting clamps for all sizes of BOP stacks. NTI can custom build a clamp to fit any manufacturer’s BOP stack size and configuration.

Gate Valve Lifter – API 7K

NTI designs and manufactures lifting devices to handle any component of the BOP stack. The gate valve lifter bolts to the existing BOP studs. This provides safe lifting points for handling and assembling BOP stacks.

BOP Lifting Systems – API 7K

NTI designs hydraulic BOP lift systems for multiple sized applications. Some of the more common BOP lift systems have been for 11” 5000 PSI stacks and 13 5/8” 10,000 PSI stacks.

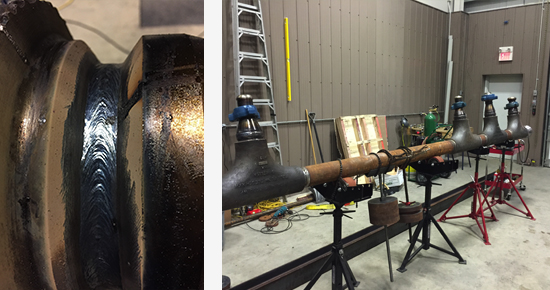

High Pressure Mud Lines – ASME B31.3

NTI designs and manufactures high pressure mud systems (5,000psi to 10,000psi) to suit the needs of any drilling rig application. NTI has fully qualified weld procedures and personnel to manufacture piping systems to the highest quality. Pictures show high pressure piping manufactured at NTI’s facility

Pipe Fittings – ASME B31.3 / ASME B16.9 / ASME B16.5

NTI designs and manufactures pipe fittings not commonly available. These include tees, target tees, end caps and reducers. NTI can design and certify flanges as OEC (other end connectors), that do not meet the standards of ASME B16.5. These include flanges that are sized for butt weld joints to schedule XXH pipe as per ASME code requirements.

Travelling Blocks – API 8C

NTI designed a travelling blocks and torque restraints (batwings) to mount a Tesco HXI 150 Ton top drive to integral rails in a stiff single mast. The blocks are designed to API 8C. NTI has upgraded blocks to accommodate more sheaves and increase load ratings.

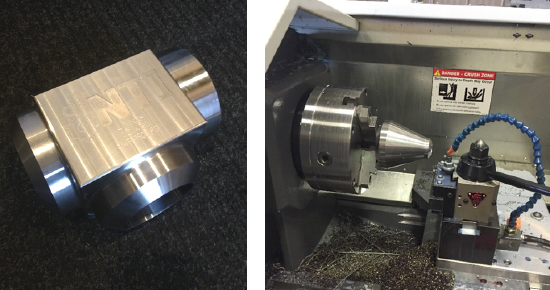

Machined Pins

NTI is capable of machining various sizes of pins. Pins are machined on a CNC lathe capable of tight machining tolerances. Pins in the picture were manufactured at NTI’s facility.

BOP Walk-a-round Systems – OH&S

NTI has designed numerous BOP walk-a-round systems to allow safe and easy access for maintenance and BOP system operations. Walkways are designed using aluminum where possible to allow for quick and easy rig up/down.

Hammer Union Wrenches

NTI has designed and developed a hammer union wrench that can make and break hammer unions with a handle. Using a handle instead of a hammer increases safety and the lifespan of the hammer unions. The wrench protects the hammer union wing from being damaged by a hammer. If necessary, the wrench utilizes a replaceable pad which can be struck with a hammer for unions that are too tight, or too stuck to break with the handle. Hammer union wrenches can be made for any size of union.

Patent Pending

Moving System Conversions – API 4F

NTI has converted numerous conventional drilling rigs from single well drilling operations to multiple well pad drilling rigs with integrated moving systems. Upgrades have included hanging the doghouse and transfer tanks from the substructure and moving system, while maintaining balanced loads for low ground pressure forces.

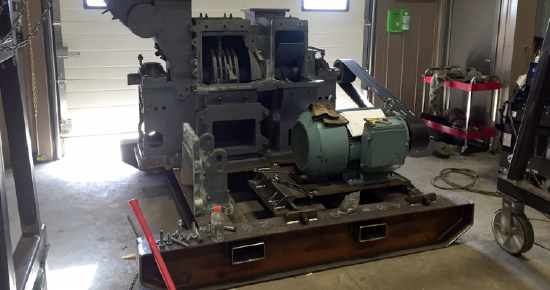

Belt Drives

NTI designs custom belt drives for running industrial equipment. Belt drive specifications, tensioners and motor specifications can be recommended by NTI. The drive in the picture below was fabricated at NTI’s location.

Risers

NTI has designed risers of various heights for catwalks, substructures and carriers.

Crowns – API 4F / API 8C / API 9B

NTI has designed new crowns for drilling rig upgrades. NIT has also upgraded existing crowns to meet higher load ratings, and in some cases even added another sheave to increase hook loads.

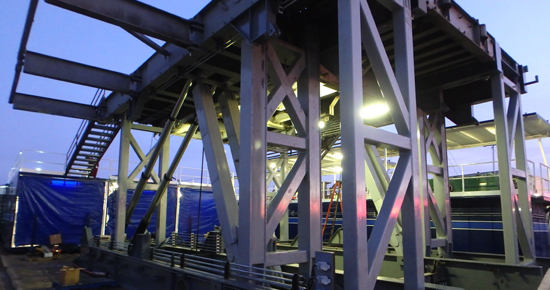

Rig Upgrades – API 4F

NTI has successfully upgraded numerous drilling rigs. Upgrades have included higher static hook loads, higher casing loads, higher setback capacities, and integrated top drives. Upgrades have also included addition of walking systems, hanging of peripheral loads for walking, and updating existing rigs to current API standards.

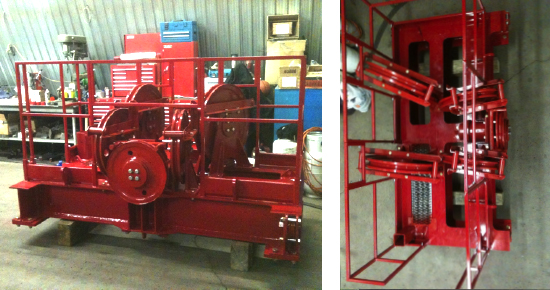

Drawworks – API 7K

NTI designed a 1200 HP DC drawworks. Full drawings and specifications for all structural and machine components were completed by NTI engineering personnel.

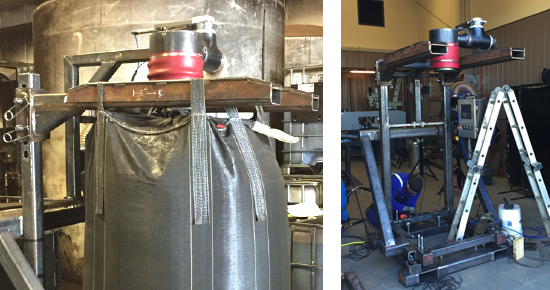

Tote Bag Scales

NTI designed and manufactured tote bag weigh scales for a fertilizer plant. The scale is fully mechanized with integrated sensors and a dust collection system for the filling of tote bags.